Hydro Richier est née d’un partenariat unique entre deux entreprises reconnues, comptant plus de 40 années d’expérience, qui apporte au marché nucléaire des solutions de service pour les systèmes de pompe. Ce partenariat innovant est au service de l’industrie nucléaire en fournissant des services d’ingénierie, d’analyse, de reconception, d’essai et d’intervention sur site pour les machines tournantes.

La vaste expérience d’Hydro Richier dans l’industrie nucléaire, associée à une fabrication de haute qualité et à d’excellentes compétences en matière d’ingénierie de pompe, fournit aux clients des solutions de service de pompe de haute qualité sur lesquelles ils peuvent compter.

Un partenariat solide

Une expérience reconnue

Ce solide partenariat permet à Hydro, Inc. de fournir ses services à Hydro Richier conformément aux exigences du projet. Cette expertise en ingénierie, associée à des technologies de pointe et à un réseau mondial, permet à Hydro Richier de proposer à ses clients des services d’excellence.

Depuis 1969, Hydro, Inc. offre une gamme de services de reconditionnement de pompes et d’ingénierie à l’industrie de production électrique. Le programme d’Assurance Qualité d’Hydro, Inc. est conforme aux exigences du règlement américain 10 CFR50 Appendix B, à la norme canadienne CSA N299, et à la section III du code ASME. Ce programme a été audité par le Comité en charge des questions d’approvisionnement nucléaire Nuclear Procurement Issues Committee (NUPIC).

Améliorations techniques

Améliorations mécaniques (ex. bagues hémisphériques de précision, ajustements serrés, concentricités, perpendicularités), améliorations métallurgiques et matériaux composites.

Analyses

Analyse hydraulique, calcul de dynamique des fluides, dynamique du rotor et qualification en conditions accidentelles.

Rétro conception

Examen, essais et analyse des composants critiques afin de saisir tous les paramètres et attributs nécessaires pour assurer la fabrication, la réparation ou les modifications.

Pour ce projet, le corps d’une pompe de charge d’une centrale nucléaire européenne avait été surpressurisé et devait être remis en état. Dans ce cas, Hydro, Inc a mis en œuvre une solution innovante en procédant à l’usinage du carter contaminé et a développé une méthode innovante pour garantir un montage correct une fois la réparation du corps achevée.

Hydro Richier a la capacité et l’expérience nécessaires dans le domaine de la rétro conception et la refabrication de pièces pour une large gamme d’équipements. Grâce à notre technologie d’usinage par mesure des coordonnées, nous pouvons efficacement scanner une pièce et numériser les données dimensionnelles. Le modèle numérique créé est utilisé pour fabriquer la nouvelle pièce, qui est ensuite numérisée à l’aide de la même technologie pour garantir le respect des dimensions de la pièce d’origine.

Services de réparation de pièces contaminées

Inspection qualité, analyse détaillée, dépannage, centrage et équilibrage du rotor.

Essai de performance pompe

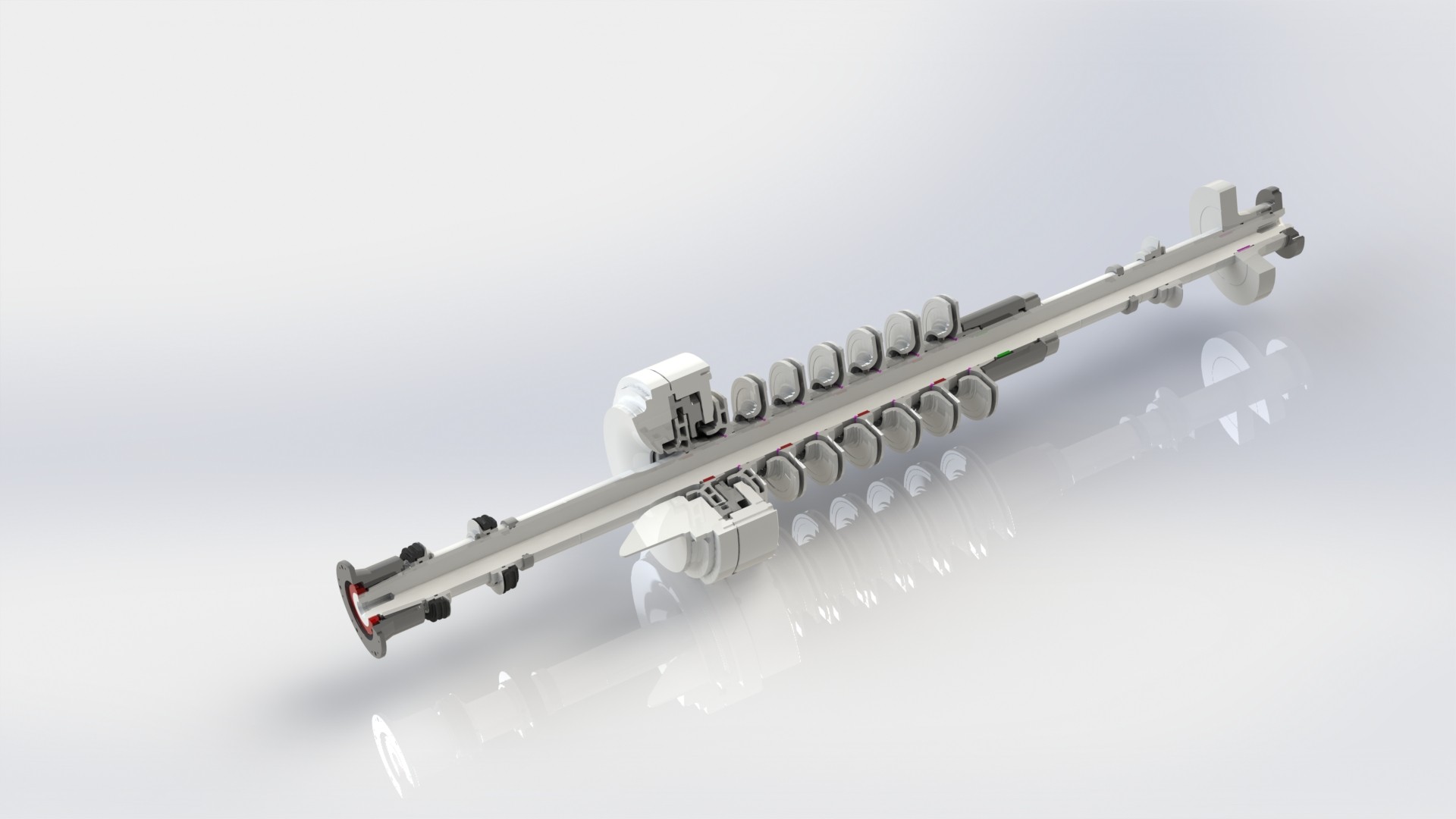

Des systèmes de pointe pour la collecte de données capables de tester les performances hydrauliques, les vibrations, la température, la puissance et d’autres facteurs pour une large gamme de pompes et d’applications.

Service sur site

Installation et démarrage de pompes, usinage sur site, services clés en main, gestion de projet, analyse vibratoire et dépannage en centrale nucléaire.

Hydro, Inc.

Un partenaire Européen

En ce qui concerne les projets dans le secteur du nucléaire, Hydro Richier, en partenariat avec le réseau mondial de centres de service de pompes dédiés au marché après-vente d’Hydro, Inc., fournit des services d’ingénierie complets pour l’industrie nucléaire permettant la réparation des équipements critiques, l’analyse des performances réelles et la résolution des problèmes.

Un technicien d’Hydro, Inc. procédant à la rétro conception de composants contaminés d’une pompe de sûreté chez un client.

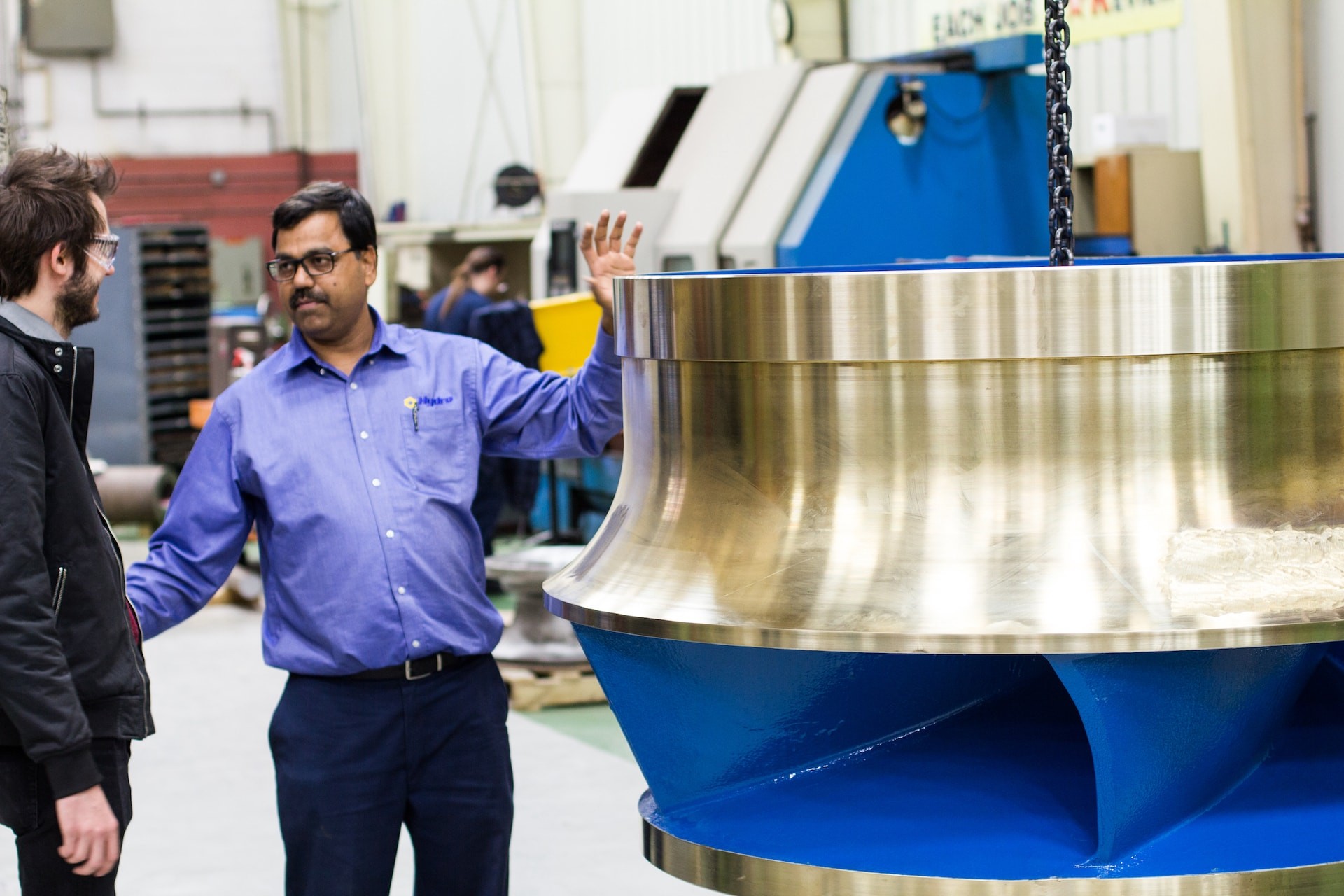

Une centrale nucléaire en Europe, aux prises avec une qualité et une livraison médiocres de la part du fabricant de l’équipement d'origine, a demandé à Hydro, Inc. de procéder àla rétro conception à la refabrication d’un rotor de pompe.

Une centrale nucléaire Européenne, faisant face à des problèmes de livraison et de qualité, avait sollicité Hydro, Inc. pour procéder à la rétro conception et la fabrication de nouvelles pièces de pompe pour un système de pompage d’eau secouru.

Hydro, Inc. a effectué la rétro conception de plusieurs pompes de sûreté ASME comme solution à l’obsolescence des matériels d’origine d’une centrale nucléaire.

Réparation d’une pompe de charge contaminée pour une centrale nucléaire Européenne.

Hydro Richier

L’exemple d’un projet réussi

Dans ce projet, Hydro Richier a entièrement usiné la roue d’une pompe de refroidissement pour une centrale nucléaire. En partenariat avec Hydro, Inc. qui a procédé à la rétro conception des composants, Hydro Richier a exécuté 100 % du processus d’approvisionnement, a coordonné le moulage avec une fonderie européenne et a réalisé l’ensemble de l’usinage pour le périmètre du projet.

Indépendance.

Expérience.

Fiabilité.

Totalisant plus de 60 ans d’expérience cumulée, Hydro Richier déploie un savoir-faire allant de la fabrication de pièces techniques et complexes de petites et grandes dimensions à des offres globales pour la production de systèmes complets. Hydro Richier propose une solution clé en main : un bureau d’études comprenant les projets d’analyse et de conception, et des équipes dédiées supervisant l’intégration hydraulique, pneumatique, électrique, l’automatisation, la programmation, le montage, le débogage ainsi que l’installation sur site.

Certifié ISO 9001, ISO 14001 et OHSAS 18001, le système qualité d’Hydro Richier garantit la rigueur tout en conservant la flexibilité d’une PME. La complémentarité des savoir-faire d’Hydro Richier lui permet d’être votre partenaire, quel que soit votre projet ou son envergure, y compris sur les marchés Européens. Hydro Richier intervient dans différents secteurs d’activité tels que l’aéronautique, le spatial, l’automobile, l’offshore, le nucléaire, l’énergie, la machine-outil et la défense.

Entièrement équipé

Pour répondre à vos besoins

Un travail de qualité commence par un atelier de qualité. Hydro Richier est pleinement équipé pour usiner tous les types de matériaux, y compris le plastique, l’acier au carbone, le bronze, l’aluminium, l’acier inoxydable et le duplex. Nous pouvons traiter en interne la quasi-totalité des processus d’usinage et de réparation, ce qui permet d’améliorer l’efficacité et d’accélérer les délais d’exécution de votre projet de réparation de pompes.

Tournage

- 2 ateliers d’une superficie de 1250 m² et 550 m²

- 2 ponts de 10 tonnes

- 2 ponts de 5 tonnes

- Chariot élévateur à fourche 3500 kg

- Tours parallèles

- 1 tour CNC CAZENEUVE Ø 900 x 4 000

- 1 tour CNC CAZENEUVE Ø 500 x 2000

- 1 tour conventionnel GIANA Ø 1 400 x 4 000

- 1 tour conventionnel SCULFORT Ø 1 250 x 7 000

- 1 tour conventionnel CAZENEUVE Ø 725 x 4 000

- 1 tour CN COMEV TITANO Ø920x4000

- Tour vertical

- 1 tour vertical CN Ø 2 500 x 1 500

- 1 tour vertical conventionnel DÖRRIES Ø 1 520 x 1 000

Alésage et fraisage

- Alésage

- 1 aléseuse TOS WHN13 CNC 5 axes 5 000 x 3 000 x 2 200

- 1 Aléseuse à commande numérique MANDELLI

- 7 axes 6 000 x 1 750 x 2 500

- 2 tables 1 400 x 1 800 indépendantes ou associées

- 1 aléseuse CNC GRAFFENSTADEN

- 5 axes 1800 x 1300 x 1500

- Fraisage

- 1 fraiseuse à portique CNC

- 5 axes positionnés HENRI LINE 4 900 x 3 800 x 3 800

- 2 fraiseuses SX HURON CNC

- 4 axes 3 000 x 1 000 x 1 000 avec sonde RENISHAW

- 2 fraiseuses SX HURON CNC

- 5 axes 2 000 x 1 000 x 1 000 axe de rotation

- 1 fraiseuse CN KIHEUNG

- 4 axes avec magasin 36 outils 3500x1200x1600

- 1 fraiseuse à portique CNC

Autres équipements

- 1 machine électro érosion à fil ONA AD35 600x600x300

- Rectification

- 1 machine de rectification de surface ELB 3 000 x 1 000 x 1 000

- Équipement informatique

- MASTERCAM V2021

- Contrôle dimensionnel

- 1 Machine de mesure tridimensionnelle 2 200 x 1 200 x 1 000

- Salle de métrologie

- FARO GAGE : précision du bras de mesure 0,005

- Jauge micrométrique carbone TESA 250 à 3 000 précision de 0,005

- Sonde RENISHAW sur machine 3 000 x 1 000 x 1 000

- TRACKER LASER LEICA AT403

Avez-vous des questions?

Pour obtenir plus d’informations sur la manière dont Hydro Richier peut répondre à vos besoins en matière de machines tournantes, veuillez remplir le formulaire de contact ci-dessous.