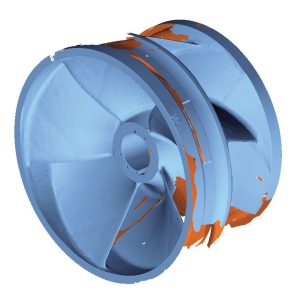

A nuclear utility had a large circulating water pump with severe vibration issues that required refurbishment in an emergency time frame. Hydro’s Aston, PA service center, which has a 50-ton crane and a history of providing quality repair for nuclear non-safety related equipment, was chosen for this work. Despite the unique challenges in machining and maneuverability presented by large pumps, the DCI and refurbishment were performed in under 2 weeks.

This pump model is an obsolete design with very few existing installations. During the refurbishment process, Hydro’s reverse engineering team captured the data necessary to create a verified model of the pump components. Developing a reverse engineered model was a crucial step in establishing a reliable source to manufacture these large components. With the verified model and Hydro’s casting and machining capabilities, the plant can plan ahead to ensure all critical components are available for future refurbishments.